We have designed and manufactured over 1500 industrial furnaces, catering to various industries such as automotive, steel, and chemical. With extensive experience and a proven track record in a wide range of furnace types, we offer a diverse range of solutions. In addition to industrial furnaces, we provide total support for related equipment and conveyors, and have successfully tackled a multitude of challenges based on different specifications and needs.

What are the differences between nitriding and carburizing? Explanation of the types and characteristics of each.

“What are the differences between nitriding and carburizing, which are commonly heard in metal surface heat treatment?”

“Require detailed information on the types and characteristics of nitriding and carburizing.”

We will provide a detailed explanation of the types and characteristics of nitriding and carburizing for engineers who have such questions or concerns.

Both are methods of metal surface heat treatment, in which heat is applied to the metal structure to bring out the required properties in the product. There are several types, and it is important to select the most appropriate heat treatment method based on the materials used and the intended use.

Choosing the wrong heat treatment method can potentially lead to problems such as insufficient hardness or reduced durability. To improve product performance, it is essential to understand the proper knowledge and use.

In this article, we will provide a detailed explanation of the characteristics of nitriding and carburizing treatments.

目次

About metal surface heat treatment

Metal surface heat treatment is used in many products not only in industrial applications but also in our daily lives. It plays a role in providing various properties such as rust resistance, wear resistance, impact resistance, and water repellency.

Heat treatment can be divided into two types: heat treatment that hardens the surface and heat treatment that modifies the surface. Among them, nitriding and carburizing are methods that modify the metal surface.

The following heat treatment methods are included in metal surface modification treatments:

- Nitriding treatment

- Carburizing treatment

- Sulphur carburizing treatment

- Boronizing

- Steam treatment

The most commonly used methods are nitriding and carburizing.

In the next chapter, we will provide detailed explanations of each heat treatment method.

About Nitriding Treatment

Let’s first discuss the characteristics of nitriding treatment.

What is a nitriding treatment?

Nitriding is a heat treatment process in which nitrogen is introduced into the surface of steel material to form a hardening layer, thereby increasing its hardness. Particularly for alloys such as chromium and molybdenum, the surface hardness is significantly increased by forming a structure of nitride compounds through a reaction with carbon. This treatment is performed at lower temperatures than the conventional hardening process, which reduces the likelihood of steel material distortion and allows dimensional accuracy to be maintained.

The temperature for nitriding treatment

The temperature for nitriding treatment is typically in the range of 500℃ to 550℃.

Nitriding hardens the metal surface at temperatures below the transformation point of the metal. Treatment at lower temperatures than conventional heat treatments offers the advantage of maintaining the dimensional accuracy of the steel material while achieving surface hardening.

The hardness and depth of the nitriding treatment

The hardness and depth of nitriding will vary depending on the depth of the nitriding layer and the material.

The following are some approximate guidelines for nitriding depth and surface hardness:

| Material | Nitriding Layer Depth | ||||

| 0.1mm | 0.2mm | 0.3mm | 0.4mm | 0.5mm | |

| Nitriding Steel | 1180 | 920 | 720 | 550 | 420 |

| Alloy Tool Steel | 1190 | 1000 | 760 | 640 | 570 |

| Chromium-Molybdenum Steel | 780 | 700 | 590 | 480 | 390 |

| Stainless Steel | 1120 | 500 | 380 | 310 | 280 |

(Unit:HV)

Types of nitriding treatments

Here are some common types of nitriding treatments:

- Gas nitriding treatment

- Salt bath nitriding treatment

- Gas soft nitriding treatment

- Plasma nitriding treatment

Gas nitriding treatment

In gas nitriding, ammonia gas is used as the atmosphere gas.

By heating ammonia gas to about 500℃, it decomposes into nitrogen and hydrogen on the surface of the steel material, and the activated nitrogen gradually diffuses into the steel material. Gas nitriding requires a longer process time compared to other methods, requiring tens of hours for the active nitrogen to penetrate the steel material. However, it results in a thicker nitriding layer and higher surface hardness.

Salt bath nitriding

Salt bathing involves immersing the steel material in a sodium chloride (salt) water solution and then heating it to perform the nitriding treatment. Some salt baths may use hazardous chemicals (such as cyanides), so precautions such as wearing protective clothing should be followed. The process involves heating the salt bath to approximately 500℃ and performing the nitriding treatment for approximately 2 hours. It completes the treatment in less time than gas nitriding, but may result in a thinner nitriding layer (approximately 10μm) and lower surface hardness.

Gas soft nitriding treatment

In gas soft nitriding, nitrogen and carbon are simultaneously injected into the surface of the steel material to improve wear resistance and fatigue strength. Various gas mixtures are used as the atmosphere gas, such as “ammonia gas and carburizing gas”, “ammonia gas + nitrogen + carbon dioxide gas”. The treatment temperature is relatively high, about 570℃, and is suitable for carbon steel and alloy steel, but caution is required when treating stainless steel. The treatment time is short, ranging from 1 to 3 hours, resulting in a thin hardening layer of 8μm to 20μm.

Plasma nitriding treatment

Plasma nitriding uses nitrogen and hydrogen as nitriding gases and operates in a vacuum atmosphere (13.3Pa to 1.3KPa). It involves a discharge between the steel material and the nitriding furnace. The glow discharge, created by applying several hundred volts of DC voltage, produces nitrogen and hydrogen ions in the nitriding gas. When these ions collide with the surface of the steel material, the temperature rises and nitriding takes place simultaneously, increasing the surface hardness. The treatment temperature ranges from 380℃ to 590℃, making it suitable for various materials, including stainless steel and titanium.

About carburizing

Next, we will explain the carburizing treatment.

Carburizing treatment

Carburizing is a heat treatment process that increases surface hardness by dissolving carbon into the metal surface. It typically uses atmospheric gases to diffuse carbon onto the surface of the product before quenching. It is commonly used on components such as gears and bearings in machine parts that are subjected to high loads, as it improves wear resistance. Hardness varies significantly depending on the carbon content, so it is important to select suitable materials for carburizing treatment. As the surface hardens, the interior retains a tough structure, making it resistant to damage even under impact loads.

Carburizing treatment temperature

Carburizing is performed at higher temperatures than nitriding, typically in the range of 850℃ to 1050℃. This allows even low-carbon steel materials to form a robust carburized case, providing excellent wear resistance, impact resistance and fatigue strength. Some processes, such as low-temperature carburizing, are performed in the vicinity of 750℃.

Carburizing treatment depth

Carburizing depth is divided into two categories according to JIS standards.

The first is the effective hardening depth, which refers to the distance from the surface to HV550 after quenching or after tempering at temperatures exceeding 200℃. In practice, tempering is often performed at temperatures exceeding 200℃, making it difficult to determine the effective hardness layer depth.

The second is the total case depth, which indicates the depth to which carbon has penetrated from the surface. It includes the area of lower carbon content and relatively lower hardness. Generally, the effective case depth is called “carburizing depth”.

Materials suitable for carburizing treatment

Materials suitable for carburizing treatment include the following types of materials.

| Material | Features | Name |

| Carbon steel for mechanical structures | Steel exclusively for carburizing and quenching. Used when high-quality carburizing and quenching is required. | S09CK S15CK S20CK |

| Chrome steel material | Materials in which chromium and manganese are added to carbon steel for mechanical structures to improve hardenability. | SCr415 SCr420 |

| Chromium-molybdenum steel | Contains alloying elements such as carbon (C), manganese (Mn), chromium (Cr), nickel (Ni), and molybdenum (Mo) in appropriate quantities. It offers hardness and strength and has strong characteristics against wear and damage. | SMC415 SCM420 |

Types of carburizing treatment

We will introduce some typical types of carburizing treatment:

- Gas carburizing treatment

- Carburizing-nitriding treatment

- Solid carburizing treatment

- Liquid carburizing treatment

- Vacuum carburizing treatment

Gas carburizing treatment

Gas carburizing treatment uses a mixture of gases such as N2, CO, H2 (endothermic conversion gases) with enriched gases such as CH4 as the atmosphere gas to adjust the carbon concentration in the furnace during processing. When low-carbon steel or low-carbon low-alloy steel that has been machined is subjected to gas carburizing treatment, it can significantly improve the surface hardness.

To avoid softening phenomena in gas carburizing treatment, it is important to suppress the formation of retained austenite. Therefore, in some cases, the carbon concentration on the steel surface is increased to 3% before carburizing treatment, which is known as “CDC” – Carbide Dispersion Carburizing process.

Carburizing-nitriding treatment

Carburizing-nitriding is a quenching treatment in which steel is immersed in carbon and nitrogen simultaneously from the surface. It is used for materials that do not harden during carburizing. It has a lower processing temperature than carburizing, which results in a shallower hardening layer. However, it causes less distortion and minimizes dimensional changes.

Even low carbon steel can be hardened by nitriding.

Solid carburizing treatment

Solid carburizing shares the same principles as gas carburizing, but has a different method of operation. Steel and carburizing materials (such as charcoal) are placed in a sealed immersion box and heat treatment is performed. Carburizing materials produce carbon monoxide when they react with oxygen and carbon. This method has a simple structure and has been used for a long time. However, it has become less popular in recent years due to its poor environmental performance and significant quality variability.

Liquid carburizing treatment

Liquid carburizing, also known as salt carburizing, is a heat treatment process performed in an aqueous sodium chloride solution. It is suitable for processing small parts and small quantities, and provides uniform treatment with minimal distortion.

Vacuum carburizing treatment

Vacuum carburizing involves reducing the pressure in a sealed furnace and then injecting acetylene gas. The acetylene gas produces active carbon by thermal decomposition, which diffuses into the material during the carburizing heat treatment. Since the treatment is carried out in a vacuum, the carburization spreads evenly without irregularities, allowing for improved surface hardness and wear resistance. It is used to improve the quality of bearing steel and tool steel.

Here are a few examples of industrial products and how they get carburized and nitride:/p>

| Type | Component name | Treatment method |

| Automotive parts | Connecting rods, crankshafts, etc. | Gas carburizing, carburizing-nitriding |

| Clutch housing | Plasma nitriding | |

| Gears, balancer shafts, etc. | Gas soft nitriding | |

| Tools | Nippers, etc. | Carburizing quenching |

| Machine parts | Gears, press parts, etc. | Carburizing-nitriding |

| Other | Shredder cutter | Carburizing-nitriding |

About nitriding furnaces and carburizing furnaces

So far, we’ve introduced nitriding and carburizing processes.

In practical mass production of products, it’s necessary to automate these processes using nitriding and carburizing furnaces. We will now explain the characteristics of each type of furnace.

Types of nitriding furnaces

Gas nitriding furnace

In the gas nitriding process, ammonia gas is used as the atmosphere gas, so the furnace must be airtight. Pit furnaces and bell-type furnaces with mufflers are commonly used for this purpose. To ensure uniform temperature distribution, pit furnaces may use large fans to mix the atmosphere inside the furnace or, in some heat treatment furnaces, the entire furnace may be rotated.

Gas soft nitriding furnace

Gas soft nitriding furnaces use either nitrogen gas or other inert gases in combination with endothermic gas. The furnace structure is similar to gas carburizing furnaces, and sealing materials are used to maintain air tightness. Due to the large amount of ammonia gas used, the exhaust gases are completely burned off with an afterburner.

Plasma nitriding furnace

Plasma nitriding furnaces treat products by discharging electricity in a vacuum environment, requiring equipment such as vacuum pumps and glow discharge power sources. These furnaces are typically vertical, with products suspended during treatment to minimize distortion. However, there can be longer processing and cooling times after treatment, so some horizontal furnaces have been introduced, with products loaded and unloaded on carts.

Types of carburizing furnaces

Now let’s discuss the types of carburizing furnaces and carburizing-nitriding furnaces.

Batch carburizing furnace

Batch carburizing furnaces process a set amount of product at a time before being replaced with new product in a batch production process. They are available in two variations: horizontal and vertical, selected based on production volume and product shapes.

Achieving uniform temperature distribution, gas concentration, and furnace sealing is critical for both types. The layout of the heating equipment and the installation of mixing fans are essential design considerations. Heating methods include burners or electrical resistance heating, with factors such as cost, quality and environmental performance influencing the choice.

Continuous carburizing furnace

Continuous carburizing furnaces operate differently than batch furnaces. Products move continuously through a constantly heated furnace.

Maintaining a uniform furnace temperature makes them more efficient and suitable for mass production.

Products are placed on trays or transported by pushers or mesh belts through stages such as preheat, carburize, diffuse, cool, and quench before moving on to the next process step.

These furnaces are particularly effective for high production scenarios, minimizing heat treatment losses.

Carburizing-nitriding furnace

Carburizing-nitriding processes can use either salt-bath-based nitriding or atmospheric gas-based methods, the latter being more common.

Carburizing-nitriding furnaces are structurally similar to carburizing furnaces and perform hardening in an ammonia gas enriched atmosphere (800-870℃). Various quenching oils are available to enhance hardening and brightness, and in some cases furnaces with controlled oil temperatures are available to optimize the treatment.

Case studies

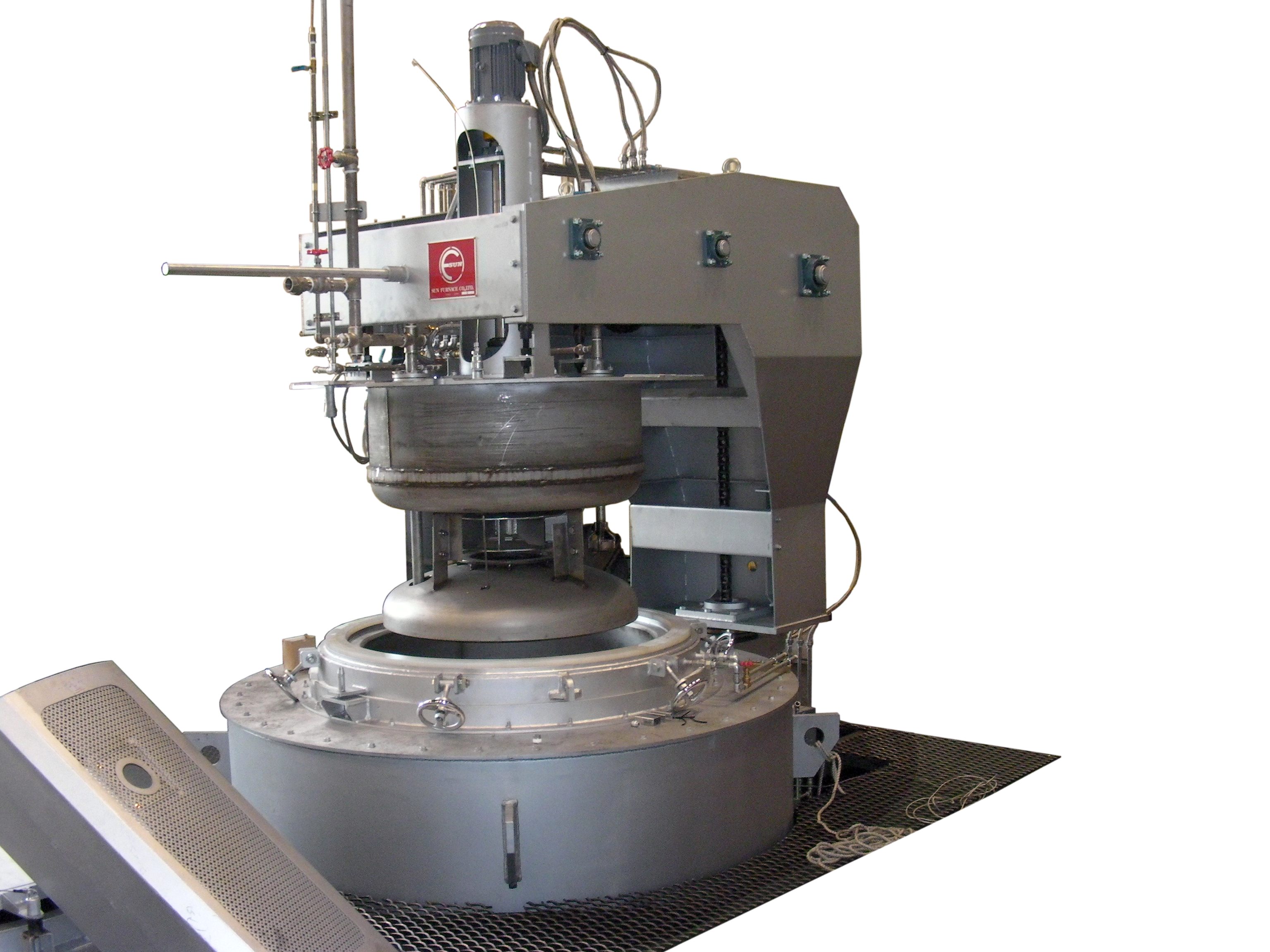

Bell type nitriding furnace

——– Installing an RC fan on the hearth can improve temperature distribution in the furnace. ——–

* Specification *

| Furnace type | Bell type |

| Effective length | φ1800×H1000 |

| Temperature | 400~650℃ |

| Atmosphere gas | Nitrogen, Ammonia gas |

| Products to be treated | Stainless steel |

| Application | Nitride |

| Processing capacity | 1000kg/ch |

* Features *

- It is possible to change the furnace atmosphere gas depending on the properties of the material and the purpose of the heat treatment.

- Special atmosphere gases other than nitrogen and ammonia gas can also be used.

- Low temperature processing is also possible.

Batch-type nitriding furnace

——– With one unit, you can switch between nitriding and carburizing. ——–

* Specification *

| Furnace type | Tray-Type |

| Effective length | W1200×H1000×L1700 (Including on the tray) |

| Temperature | 350~600℃ |

| Atmosphere gas | Nitrogen, Hydrogen, Ammonia gas, Atmosphere, RX gas |

| Products to be treated | Stainless steel |

| Application | Nitride, Carburizing |

| Processing capacity | 2700kg/ch |

* Features *

- Heat treatment programs with more than 10 patterns and 30 steps can be registered. This allows flexible heat treatment selection based on the application.

- Temperature control and gas supply operations are automated by the program, increasing operational efficiency.

- It is possible to perform heat treatment according to the application without the need for separate installations of nitriding and carburizing furnaces.

Pit-type drip carburizing furnace

——– The versatile furnace can be used as both a quenching and tempering furnace depending on the application. ——–

* Specification *

| Furnace type | Pit-type |

| Effective length | φ900×H2500 |

| Temperature | 450~950℃ |

| Atmosphere gas | Nitrogen, Methanol decomposition gas, Propane gas |

| Products to be treated | Metal material(Iron-based) |

| Application | Carburizing, Quenching, Tempering |

| Processing capacity | 3000kg/ch |

* Features *

- Gas carburizing, decarburization annealing, and gas nitriding, depending on the application.

- Due to the effective dimension of H2500, heat treatment of long parts is also possible.

- It is possible to generate carburizing gas from methanol inside the furnace for heat treatment.

- Changing the atmosphere gas is possible, allowing heat treatment of small quantities and various types.

Frequently Asked Questions

Q:Can non-ferrous metals such as aluminum and titanium be nitrided?

Some non-ferrous metals, including titanium, can be nitrided.

Q:Will the product deform during nitriding treatment?

Nitriding will cause the product to expand.

The expansion is about 3-5% of the nitriding depth for steel and about 6-10% for stainless steel.

Q:What is the appropriate carbon content for materials to be carburized?

Carburizing treatment is suitable for low carbon alloy steel (0.05-0.1%) to those with up to 0.2% carbon content or more than 0.85% carbon steel. Carburizing is a technique that originally involved diffusing carbon into relatively inexpensive low-carbon steel to increase surface hardness. The higher the carbon content diffused onto the surface of the steel material, the greater the increase in surface hardness, and it is also possible to achieve HRC60 or higher.

Summary

We have explained the characteristics of nitriding and carburizing processes.

There are several differences between nitriding and carburizing, with the main difference being the processing temperature. Nitriding is performed at about 500℃, while carburizing is performed at about 900℃, resulting in higher surface hardness in the case of carburizing.

On the other hand, nitriding may have a lower surface hardness, but it causes minimal dimensional changes and allows improvement in wear resistance, fatigue resistance and corrosion resistance. There are differences in the types of steel materials suitable for each process. Carburizing is particularly effective on high-carbon steel, while nitriding can be applied to non-carbon stainless steel. Depending on the properties and applications of the product material, it is necessary to select the appropriate heat treatment method and consider the configuration of the heat treatment furnaceWhen introducing a heat treatment furnace, it may be beneficial to consult with a specialized manufacturer who can provide comprehensive support from specification determination and trial processing to actual operation and after-sales service.

Industrial furnace manufacturer, Sun Furnace, proposes custom-made atmosphere gas generation devices tailored to your application based on the know-how gained from manufacturing more than 1,500 industrial furnaces.

We also offer free technical consultations, so please feel free to contact us.

Learn more about Sunfurnace’s vacuum furnaces

Learn more about Sunfurnace’s atmosphere furnaces

Learn more about Sunfurnace’s rotary kiln furnaces